In today’s fast-paced logistics industry, achieving real-time visibility in supply chain operations is pivotal. Embracing cutting-edge technologies is no longer a matter of choice but a necessity for businesses striving to stay competitive. This blog explores the transformative impact of integrating Senitron’s RFID solutions with Brocode’s ERPNext system, offering a powerful advantage in logistics management.

The Emergence of RFID in Supply Chain Management

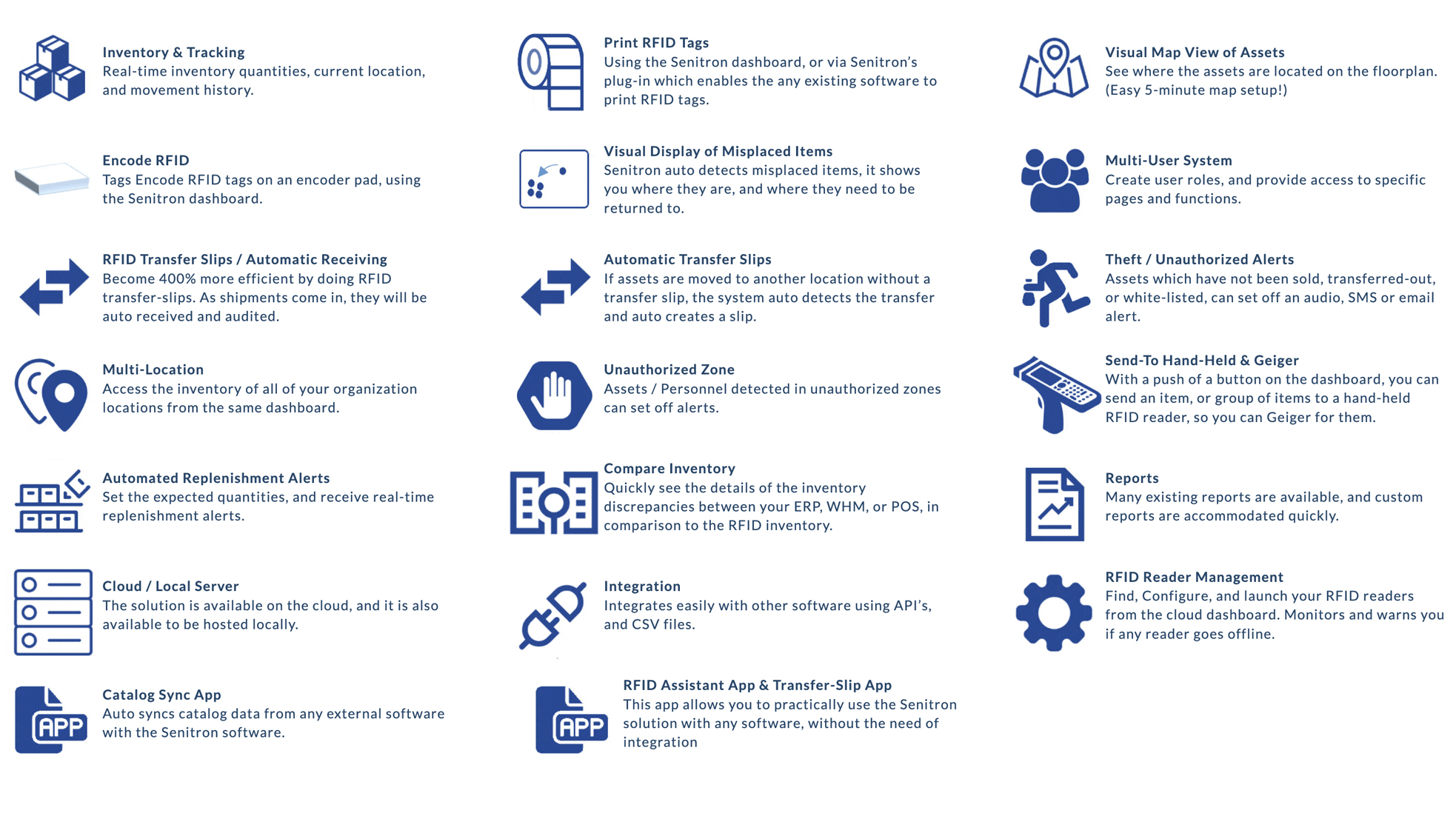

RFID (Radio Frequency Identification) technology has become a game-changer in supply chain management. By enabling real-time tracking of assets, RFID technology offers a level of efficiency that traditional barcoding systems cannot match. Senitron’s RFID solutions stand out with their ability to provide accurate, scalable, and reliable tracking capabilities. These solutions offer businesses a comprehensive approach to manage their inventory, ensuring every item’s location and status is monitored in real-time.

Brocode’s Integration of ERPNext with RFID

Brocode, a leading logistics provider, has embraced ERPNext, a dynamic ERP (Enterprise Resource Planning) software, to streamline its business processes. The integration of Senitron’s RFID technology into ERPNext has created a synergy that drives operational efficiency and transparency. This combination allows Brocode to have a holistic view of their supply chain, enabling them to make informed decisions quickly and maintain a high level of responsiveness to customer needs.

Advantages of Combining RFID with ERP Systems

Integrating RFID technology with ERP systems like ERPNext provides a host of benefits. It ensures precision in inventory tracking and greatly reduces the likelihood of human error. The rich data obtained from RFID tags, when combined with ERPNext’s analytical tools, provides valuable insights for strategic planning and supply chain optimization. This integration enables businesses to react swiftly to market dynamics, anticipate challenges, and efficiently manage resources.

Businesses across various sectors have witnessed a significant boost in supply chain efficiency after adopting integrated RFID and ERP solutions. Case studies reveal how such integrations have led to substantial improvements in operational processes, cost reductions, and increased customer satisfaction. These success stories exemplify the tangible benefits of adopting a technology-driven approach in supply chain management.

Combining the features and benefits of ERPNext and Senitron’s RFID solutions, we can envision an integrated ERP solution that leverages the best of both worlds – the comprehensive business process management of ERPNext and the advanced tracking and data accuracy of RFID technology. This integrated solution would represent a significant advancement in enterprise resource planning, particularly for businesses looking to optimize their supply chain and inventory management processes.

At its core, this combined solution offers an unparalleled level of real-time visibility into every aspect of the supply chain. With Senitron’s RFID technology, items can be tracked with exceptional accuracy as they move through various stages of the supply chain. This data is then seamlessly integrated into the ERPNext system, providing a live, comprehensive view of inventory levels, shipment status, and logistical operations. The real-time data captured by RFID tags ensures that the information within the ERP system is always up-to-date and reflective of the current state of the supply chain.

The integration of RFID technology into an ERP system like ERPNext also dramatically improves inventory management. It enables automated tracking of stock levels, reducing the likelihood of overstocking or stockouts. This is particularly beneficial in industries where inventory management is critical to business success, such as retail, manufacturing, and logistics. The RFID system’s ability to provide detailed information on each item – including its location, movement history, and current status – enhances the ERP’s capability to manage these items more effectively.

From an operational standpoint, this integrated solution streamlines processes and reduces manual labor, particularly in tasks like inventory counts, order processing, and tracking shipments. The efficiency gained from automating these processes not only saves time but also significantly reduces the potential for human error, leading to more accurate and reliable data.

In addition to operational efficiency, this solution offers powerful analytical capabilities. The rich data collected by RFID tags, when processed through ERPNext’s analytics tools, can provide valuable insights into inventory trends, supply chain bottlenecks, and customer demand patterns. This level of insight supports more informed decision-making, allowing businesses to respond proactively to market changes and optimize their operations for better profitability and customer satisfaction.

Furthermore, the flexibility and customization potential of ERPNext, combined with the scalability of Senitron’s RFID solutions, means that this integrated system can be tailored to fit the unique needs of various businesses, regardless of size or industry. Whether it’s a small business looking to improve its inventory management or a large corporation seeking to optimize a complex global supply chain, this solution can be adapted to meet specific requirements.

In conclusion, the integration of Senitron’s RFID solutions with ERPNext creates a powerful ERP solution that offers real-time supply chain visibility, enhanced operational efficiency, and sophisticated analytical capabilities. This integration represents a significant step forward in the way businesses manage their operations, providing them with the tools they need to succeed in today’s fast-paced and ever-changing business environment.

- Written by: brocode

- Posted on: February 15, 2024

- Tags: Django, ERP, Password Management, SEO, web development